How to Put Down a Wood Floor That’s Pre-Finished

Install Durable and Warranted Pre-finished Hardwood Flooring in Your Kitchen Using Tongue and Groove Joinery for Row-by-row Construction

Think again if you imagine a pre-finished hardware flooring installation is not durable enough to withstand kitchen traffic, children's toys and pets. Today's pre-finished hardwood flooring systems may offer 25-year finish warranties and lifetime structural warranties--not to mention tools, techniques and interlocking tongue and groove joinery that make DIY installation a snap.

Read More

Research Available Pre-finished Hardwood Flooring Systems on the Internet

Investigate pre-finished hardwood flooring products on the Internet and at your home improvement store before deciding for or against its use in the kitchen. Many manufacturers offer long-term warranties according to the pricing and quality rating of their products.

Prepare Yourself, Your Tools and Your Kitchen to Control Dust

Lift wooden thresholds prior to sealing kitchen doorways and cabinetry with plastic and tape to control dust. Position a fan to draw dust out the open window. Wear a dust mask and install a vacuum bag on your circular saw.

Cut Tile Grout Seams and Underlayment with Circular Saw

Cut tile grout seams with a diamond-tipped blade intended for cutting stone and masonry. Adjust the saw blade depth to cut only through grout and the first wooden under layer. Pry up the plywood underlayment, removing it with the tiles.

Store the Hardwood Flooring in the Kitchen for Several Days

Open and store the pre-finished hardwood flooring in the kitchen three to four days before beginning the installation. The product should acclimate to the same temperature and moisture content as the subfloor in the environment where you will install it.

Start Installing the Pre-Finished Hardwood Flooring at an Exterior Wall

Snap a chalk line about 3 inches from as exterior wall--that is the width of the plank plus a 1/2 inch expansion gap. Align the plank on the chalk line and nail it along the outer edge.

Notch around Obstacles and Interlock Planks at the Ends

Mark cut lines on planks in correct locations and dimensions of obstacles such as pipes and air vents. Notch along the cut lines with a jigsaw. Fit planks together with interlocking tongue and groove joints.

Using a Special Hardwood Flooring Stapler on the Remaining Rows

Fit the groove of the next pre-finished hardwood flooring plank over the tongue portion of the previous row. Secure it with a special stapler that positions itself against the tongue edge to drive in a staple at the correct angle.

Stagger Planks with obvious Grain Patterns and Colors

Remove all planks from their cartons and lay them out on the floor to mix their colors and grain patterns prior to installation. Stagger planks with noticeable variations so they blend rather than standing out in an eye-catching group.

Undercut Door Casings and Install the Planks underneath

Undercut door casings enough to install the planks underneath. Rest a side saw on a scrap hardwood plank to achieve the correct elevation and cut away the casing. Notch the planks to be installed, slide them beneath and secure them.

Install Strips of Quarter-round Molding over the Expansion Gap

Install or reinstall strips of quarter-round molding along the floor at the bottom of the cabinets and baseboards when the pre-finished hardwood flooring installation is complete. The molding will hide the expansion gap left around the perimeter.

Related Tips

Blog Articles

Have You Heard of Landscape Glue?

You love the rustic charm of a gravel walkway, but the constant scattering of stones across your lawn and patio can be a real headache. Whether it’s from pets, lawn mowers, or just foot traffic, it seems impossible to keep those stones in place. Sound familiar? Well, Brian shows us a simple DIY method using landscape glue to keep your gravel path looking pristine and, more importantly, in place.

How to Remove Candle Wax Drips: Two Effective Methods

Candles create a warm and inviting atmosphere, but those pesky wax drips can be a real headache. Luckily, Brian shows us a couple of effective methods to tackle this issue, and they involve two very different temperatures: hot and cold. Here, we'll explore two effective methods: one using cold and the other using heat.

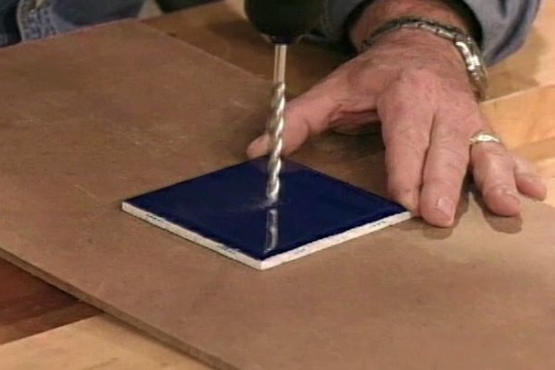

Guide to Hanging on Masonry Walls

Ever wondered how to hang that picture frame or shelf on a brick or concrete wall? It can seem daunting, but with the right tools and techniques, it's a straightforward DIY project. This guide breaks down two common methods: using concrete screws and using anchors, making it easy for you to tackle your next hanging project.