How to Choose the Right Oscillating Tool Blade for the Job

This post is in partnership with Zenith Industries. The opinions and recommendations are my own.

Choosing the RIGHT BLADE for an Oscillating Tool or Multi-Tool is Crucial

The oscillating or multi-tool blades and accessories featured in this video are from Zenith Industries. For more information Click Here.

As its name implies, the multi-tool or oscillating tool can perform a lot of different functions simply by changing the tool head. It can sand, rasp, file and, of course, cut. It’s especially useful in tight situations where conventional power tools just can’t reach.

The secret to getting the most out of a multi-tool, especially when it comes to cutting, is using the right blade. By “right”, I mean the blade best suited to the job at hand and one that’s high quality. This video shows numerous jobs that can be done with an oscillating tool and how to select the best blade for each. The blades used in this video are all available from Zenith Industries.

One point I’d like to make before going on: the multi-tool is not a replacement for more familiar power tools like circular saws, jigsaws, and reciprocating saws. In many cases, these tools are far more efficient when it comes to cutting than an oscillating tool. However, there are many tasks and situations where the oscillating tool shines and you’ll find it a welcome and handy addition to your tool collection.

One point I’d like to make before going on: the multi-tool is not a replacement for more familiar power tools like circular saws, jigsaws, and reciprocating saws. In many cases, these tools are far more efficient when it comes to cutting than an oscillating tool. However, there are many tasks and situations where the oscillating tool shines and you’ll find it a welcome and handy addition to your tool collection.

Multi-tools don’t rotate like a circular saw or reciprocate like a jigsaw. Instead to oscillate or move back and forth through a small arc, usually only three or four degrees. This alternating movement happens very rapidly, over 20,000 times per minute.

For clean, fast cuts through wood, a chrome vanadium blade featuring a Japanese-style tooth design with a double row of alternating teeth would be my choice. The spacing of the teeth expels sawdust efficiently and reduces any tendency to burn. This blade would be a good choice for plunge cutting in laminate flooring as well as flush cutting door jambs and casings. The fine-tooth version is a good choice for plunge cuts in drywall when, for example, installing electrical boxes.

For clean, fast cuts through wood, a chrome vanadium blade featuring a Japanese-style tooth design with a double row of alternating teeth would be my choice. The spacing of the teeth expels sawdust efficiently and reduces any tendency to burn. This blade would be a good choice for plunge cutting in laminate flooring as well as flush cutting door jambs and casings. The fine-tooth version is a good choice for plunge cuts in drywall when, for example, installing electrical boxes.

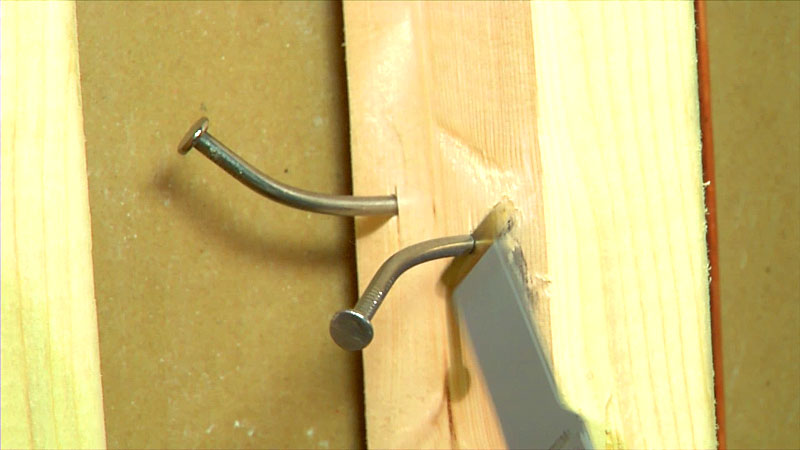

If you plan on cutting bolts, trimming off bent nails, or sawing through pipe, particularly in confined areas, then you’ll want a blade that features cobalt steel teeth.

If you plan on cutting bolts, trimming off bent nails, or sawing through pipe, particularly in confined areas, then you’ll want a blade that features cobalt steel teeth.

Bi-metal blades are designed to cut through both metal and wood. This would be the blade of choice when it comes to cutting wood that has embedded or hidden nails and for separating nailed together framing members.

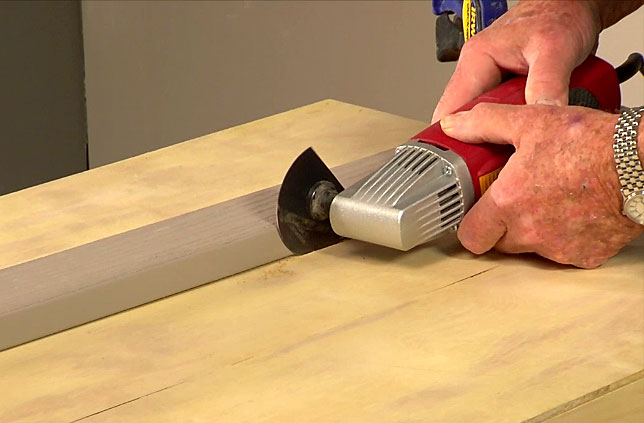

Semi-circular blades made from high-speed steel offer excellent straight-line cutter and because the teeth zero offset, can even be used with a straight edge or cutting guide. This is also a good choice for terminating cuts without over-cutting into adjacent surfaces.

Semi-circular blades made from high-speed steel offer excellent straight-line cutter and because the teeth zero offset, can even be used with a straight edge or cutting guide. This is also a good choice for terminating cuts without over-cutting into adjacent surfaces.

Carbide grit blades have no teeth, but instead, have tough carbide grit vacuum-brazed to their cutting edges. These blades come in a variety of shapes and can be used for smoothing cut ceramic tile, cleaning out cracks when repairing concrete, and shaping cut edges on wood. There are also diamond-grit versions that excel when it comes to removing tile grout or plunge cutting in concrete board.

Watch the video to see these and other multi-tool blades and attachments in action.

Recommended Articles

The How’s and Why’s of Upgrading a Central AC System

A step-by-step video demonstration showing removal and replacement of a central air conditioning system. Includes advantages of new, state-of the-art AC systems.

If You’ve Got a Project That Involves Demolition, You’ll Want to Know About This Tool.

I try out a new tool designed and engineered to do one task exceptionally well -- demolition.