RON HAZELTON:

Ardina and Johnny Williams of Cooler, Georgia have asked for a house call. They want to install a kitchen exhaust fan and I'm going to see if I can help them out. I understand we've got a kitchen project today.

JOHHNY:

Yes.

ARDINA:

We need a Hood Vent installed.

RON HAZELTON:

Okay, let's go in and take a look around. Is there one there now?

ARDINA:

No.

JOHHNY:

No.

ARDINA:

There's nothing,

RON HAZELTON:

Okay.

ARDINA:

This is where it needs to go.

RON HAZELTON:

You don't even have one. You've never had one.

ARDINA:

No, never. Since we moved in.

RON HAZELTON:

Okay - and why do you want one now, have you decided?

ARDINA:

Well every time we turn on the stove in any way it sets off our heat and smoke detector on the other side of the doorway.

RON HAZELTON:

Now have you purchased the unit yet?

JOHHNY:

Yes.

ARDINA:

Yes. We have it out in the garage.

RON HAZELTON:

Okay, would you bring it in. I just want to check a couple of things.

[BOTH SPEAK AT ONCE]

JOHHNY:

Yes.

RON HAZELTON:

Okay. You need 2 things to install a range hood. Electricity which we have right here. And a way to direct the exhaust. Now we could go up with the exhaust through the cabinets. But in this case, you'd see the exhaust pipe right here.

So instead, we're going to go through the wall. Which means we not only have to go through this wall board right here, but also through the brick wall on the outside of the house.

Johny and Ardina start by checking to make sure there's enough space between the cabinets.

ARDINA:

I think that will work.

RON HAZELTON:

Then we'll find the center of the wall. And follow the manufacturers' detailed instructions to mark the position for the cut out. This is what we're going to cut out right here.

X marks the spot for the cut out. Now this is where the electrical wire will come through right here. This is where the exhaust will go out. And those of course have to match up with these same openings in the back of the exhaust fan.

So now it's time to do some cutting. The idea is to push it through the wall. There you go. Using a wallboard saw, Johnny cuts along the lines we've just drawn. As is often the case with home improvement, the empty space we expected to find behind the wall is occupied by a copper water pipe.

The only choice is to detour the pipe around the opening. To do this, we remove the cabinet and enlarge the opening in the wall. While the wall is open, we run the new electrical wire for the range hood. Then re-route and resoder the copper pipe.

To close up the opening, we'll attach one by 3 cleats to the inside of the wall at the top and bottom. Secure the new wallboard at these cleats and then patch the seams with joint tape and compound. Well it was quite a detour, wasn't it?

But we have gotten that pipe out of the way and right now we're looking at the backside of the exterior brick wall. We're going to start cutting through now. I'm going to do that by boring 4 holes at each corner where we want the exterior hole to be.

Going to use a carbide-tipped bit and a hammer drill. Now this drill actually hammers as it rotates. It’s going to allow us to go through that brick a lot faster. Johnny and I share the drilling duty. And before long, we have the corner holes bored out.

[BOTH SPEAK AT ONCE]

RON HAZELTON:

You okay.

JOHHNY:

Yeah.

RON HAZELTON:

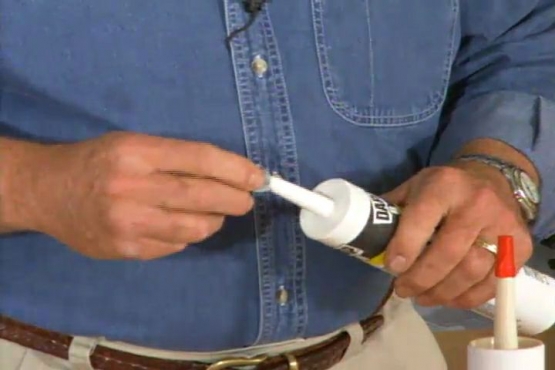

That was fast. For the outside, we drill a series of holes between the corners to perforate the opening. Then using a hammer and chisel, we remove the loose brick and mortar. We're going to start our actual installation here on the outside by putting in this wall cap.

This is where the exhaust air will actually exit the building. Now attached to that will be a short piece of duct. This was 24 inches long when we got it. We simply cut it down to length. It will slip up inside here. And this entire unit will go through the wall and we'll seal it around the edges here with some caulk and then attach it on the inside to the range hood.

I'll use sheet metal screws to attach the duct to the wall cap. And then seal the joint with duct tape. A heavy bead of masonry adhesive will secure the cap to the brick wall and keep it sealed from wind and weather. Once the duct has come through the wall, I use tin snips to cut the corners.

And then bend the edges back flush with the wall. A flange around the duct makes a tight seal to the hood. Because the underside of the cabinet is recessed, we'll need to install cleats to provide a mounting surface for the hood.

Ardina drives screws through the bottom of the cabinet to attach the cleats. At the electrical outlet, I cut back the insulation and then make the connections for the wiring. Finally we install 4 mounting screws to the cleats, driving them only half way in so that we can slip the slotted mounting holes over the heads.

We are approaching the moment of truth okay. You'll have 2 jobs. One will be to take that electrical wire over there and feed it through this hole right here, this connector.

ARDINA:

Okay.

RON HAZELTON:

Now gently pull it through.

ARDINA:

All right.

RON HAZELTON:

And then we put 4 screws in up there, we want to locate these large holes right here just below the heads of the screws. Push this up on the screws and we're going to slide it back to the wall -

ARDINA:

All right.

RON HAZELTON:

And then tighten the screws up. Next, we connect the electrical wires to the hood. And replace the access panel. Finally we snap the grease filter in place. All right, take it way and I don't hear any smoke alarm.

ARDINA:

Yeah. We've got good ventilation now.

RON HAZELTON:

Well I guess we solved that problem.

ARDINA:

Yes and we really appreciate your coming to help us out.

RON HAZELTON:

Oh you're very welcome. And the other problem, the one we found inside the wall.

ARDINA:

We're glad we didn't have to deal with it alone.

RON HAZELTON:

Ah, you could have handled it. Johnny, pleasure working with you. The smell of those burgers brought the kids running. Great idea. Let's eat.

JOHHNY:

Let's eat.